PRODUCTS

Latest News

Galvanized Steel: Types, Uses, Benefits.

2024-07-31

Simple classification of stainless steel

2024-07-31

Form classification of stainless steel

2024-07-31

What is galvanized steel plate

2024-07-31

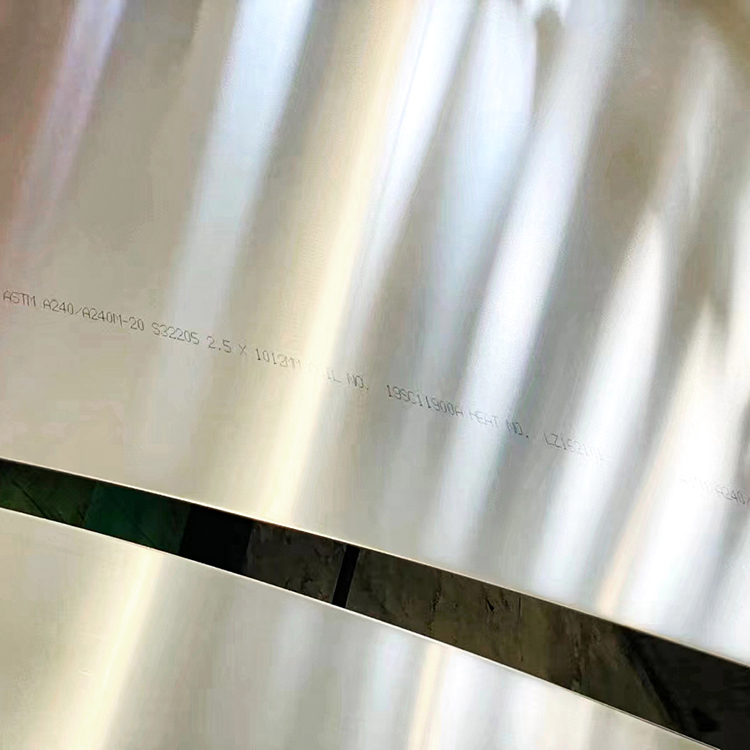

304 Stainless Steel Plate

One of the most versatile and commonly used stainless steels on the market, Grade 304 stainless steel is the most standard used alloy of this type. Essentially, Grade 304 is an austenitic chromium alloy which is also known as an “18/8” stainless as the make-up of the steel is 18% chromium and 8% nickel.

Category:

Description

304 contains 18 - 20% Chromium (Cr). Chromium is the essential chemical in all stainless steel and it is that which forms the thin passive layer that makes the metal "stainless"

304 also contains 8-10.5% Nickel (Ni). This is added to make the Austenitic structure more stable at normal temperatures.

The nickel also improves high-temperature oxidation resistance makes the steel resistant to stress corrosion cracking.

Where the steel is to be stretched formed a lower percentage (8%) of nickel should be selected. If the steel is to be deep drawn a higher percentage is better (9% or more).

In addition a number of other chemicals may be present but these are expressed as maximum permited levels with the exception of the increased quantity of carbon required in 304H - i.e. a minimum of .04% and a maximum of 0.10%

*Maximum carbon content of 0.04% acceptable for drawn tubes

What’s the Difference Between Grade 304 ,304L & 304H Stainless Steel?

There are hundreds of different grades of stainless steel on the market. Each of these unique formulations of stainless steel offer some degree of corrosion resistance above and beyond that of plain steel.

The existence of these stainless steel variants can cause some confusion—especially when the names & formulations of two stainless steel alloys are almost the same. This is the case with grade 304 and 304L stainless steel.

Chemical Composition - Stainless Steel 304/304L

These three alloys are remarkably similar—but there is one key difference. In grade 304 stainless, the maximum carbon content is set at 0.08%, whereas grade 304L stainless steel has a maximum carbon content of 0.03%. The “L” in 304L can be interpreted as meaning extra-low carbon.

This difference of 0.05% carbon content produces a slight, but marked, difference in the performances of the two alloys.

The Mechanical Difference

Grade 304L has a slight, but noticeable, reduction in key mechanical performance characteristics compared to the “standard” grade 304 stainless steel alloy.

Typical Mechanical Properties-Stainless Steel 304/304L

Physical Properties

Mechanical Properties

Electrical Properties

Thermal Properties

Design Features - Stainless Steel 304/304L

Oxidation resistance up to 1650°F for continuous service and up to 1500°F where cyclic heating is involved.

General purpose corrosion resistance.

Non-hardenable except by cold working.

Non-magnetic except when cold worked.

May be susceptible to chloride stress corrosion cracking.

Used where field working is employed.

Typical Applications - Stainless Steel 304/304L

Sanitary

Dairy and food processing

Heat exchangers, evaporators

Feedwater heaters

Tensile Requirements - Stainless Steel 304/304L

Tensile Strength (KSI): 70

Yield Strength (KSI): 25

Each alloy represents an excellent combination of corrosion resistance and fabricability. This combination of properties is the reason for the extensive use of these alloys which represent nearly one half of the total U.S. stainless steel production. The 18-8 stainless steels, principally Alloys 304, 304L, and 304H, are available in a wide range of product forms including sheet, strip, and plate. The alloys are covered by a variety of specifications and codes relating to, or regulating, construction or use of equipment manufactured from these alloys for specific conditions. Food and beverage, sanitary, cryogenic, and pressure-containing applications are examples.

Alloy 304 is the standard alloy since AOD technology has made lower carbon levels more easily attainable and economical. Alloy 304L is used for welded products which might be exposed to conditions which could cause intergranular corrosion in service.

Alloy 304H is a modification of Alloy 304 in which the carbon content is controlled to a range of 0.04-0.10 to provide improved high temperature strength to parts exposed to temperatures above 800°F.

For example, the ultimate tensile strength (UTS) of 304L is roughly 85 ksi (~586 MPa), less than the UTS of standard grade 304 stainless, which is 90 ksi (~620 MPa). The difference in yield strength is slightly greater, with 304 SS having a 0.2% yield strength of 42 ksi (~289 MPa) and 304L having a 0.2% yield strength of 35 ksi (~241 MPa).

This means that if you had two steel wire baskets and both baskets had the exact same design, wire thickness, and construction, the basket made from 304L would be structurally weaker than the standard 304 basket.

Why Would You Want to Use 304L, Then?

So, if 304L is weaker than standard 304 stainless steel, why would anyone want to use it?

The answer is that the 304L alloy’s lower carbon content helps minimize/eliminate carbide precipitation during the welding process. This allows 304L stainless steel to be used in the “as-welded” state, even in severe corrosive environments.

If you were to use standard 304 stainless in the same way, it would degrade much faster at the weld joints.

Basically, using 304L eliminates the need to anneal weld joints prior to using the completed metal form—saving time and effort.

In practice, both 304 and 304L can be used for many of the same applications. The differences are often minor enough that one isn’t considered massively more useful over the other. When stronger corrosion resistance is needed, other alloys, such as grade 316 stainless steel, are usually considered as an alternative.

ASTM A213 / ASME SA213

ASTM A213 / ASME SA213 is a America specification for stainless steel boiler, super heater, heat exchanger tubes, executed by most world stainless steel seamless tubes mills and factories, minimum wall thickness required in A213 seamless tube, or average wall thickness as customers requirement, tight tolerance of outside and wall thickness stated as A213 standard or A1016

Cold Rolled Commercial Steel Vs. 304 Stainless Steel

Cold rolling steel is a method that is used to provide a dense, dimensionally precise piece of steel. The most commonly used grade of stainless steel is 304. All stainless steels are a specific alloy mix.

Cold Rolled Steel

Cold rolled steel, also called CRS, is a process used to finish steel. Hot rolled steel is steel that is still warm enough to be malleable and run through pressure rollers. After cleaning, when the steel has cooled and is no longer elastic, the steel is then put through power rollers and cold rolled. This produces a product that has a fine, smooth finish.

304 Stainless Steel

The most commonly used grade of stainless steel is 304. Another name for 304 is 18/8 because it is 18 percent chromium and 8 percent nickel. These additions make it resistant to corrosion.

CRS vs. 304 Stainless Steel

The difference between CRS and 304 stainless steel is that CRS is a process and 304 is an alloy. Steel, hot or cold rolled, will rust and corrode. It is used in applications where that is not a consideration. Stainless steel is an alloy with chromium and nickel that prevents rust and corrosion. It is used where rust and corrosion will be a problem. It is possible to buy 304 cold rolled stainless steel.

Advantages of Stainless Steel 304 Pipes

Strength

Stainless Steel is a chromium-based alloy known for its incredible anti-rust properties. But along with this, Stainless Steel alloys are also used due to their incredible strength. Stainless Steel 304 has incredible strength and durability. Its strength is one of the most sought-after traits of grade 304 SS. Stainless Steel 304L Pipes and 304 Pipes are solid and retain their strength at extreme temperatures.

Sanitization

Stainless Steel 304, 304 L, and almost every grade of Stainless Steel is brilliant at repelling corrosion. As a result of this property, Stainless Steel grade 304 Pipes also have the property of repelling the growth and spread of microbes and dirt on the surface of the Pipes. Hence, it is often used in applications that have a primary need for sanitization and monitoring cleanliness. Additionally, Stainless Steel 304 Pipes are incredibly easy to maintain. They can be cleaned very easily. Hence, Stainless Steel 304 Pipes are used at hospitals, kitchens, food processing localities, etc., where cleanliness is a requisite.

Corrosion Resistance

AS its name suggests, Stainless Steel is a material that prohibits rusting and corrosion even in extreme temperature and weather conditions, including high-pressure areas. The chromium present in stainless Steel reacts with oxygen to create a chromium oxide film or layer that settles on the surface of the metal. This layer is what protects the Pipes from corroding. It is a self-reparatory layer that does not require maintenance or refurbishing.

But what sets grade 304 apart is the addition of molybdenum to the alloying composition making it an austenitic grade of stainless Steel. Austenitic Steel has enhanced corrosion resistance. Hence, for applications in extreme conditions, Stainless Steel 304 Pipes are an ideal choice.

Recyclability

Stainless Steel 304 Pipes are entirely recyclable. Once its utility purposes have been outlived or fulfilled, it can be recycled and re-forged. When stainless Steel is recycled, it does not lose any of its properties. All of its chemical, physical, and mechanical properties remain intact. About 70% of existing Stainless Steel artifacts are made out of recycled material.

Durability

Even though Stainless Steel 304 Pipes are lightweight, they are solid. They won’t succumb to external weights and pressure. Hence, it is said that it is one of the most durable materials. Stainless Steel 304 Pipes can withstand extreme temperatures as well as extreme pressures.

Corporate Honor

Customer Photo

Cooperation Brand

FAQ

How to contact us?

If you are interested in our products, please feel free to contact us at any time. You can contact our product manager through email or the message board at the bottom of the page.

What are your main products?

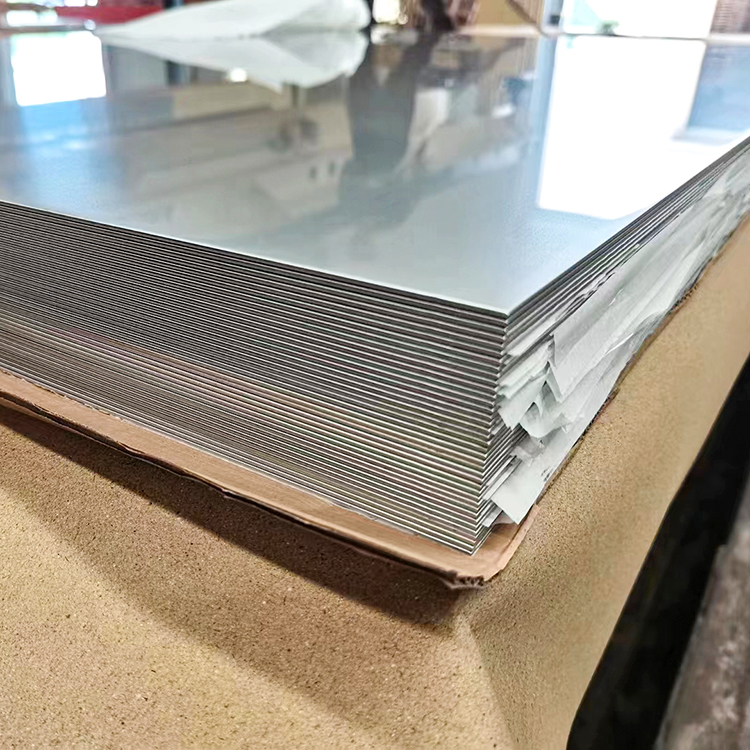

Galvanized steel plates, color coated galvanized steel plates, galvanized steel pipes, stainless steel plates, stainless steel pipes, stainless steel castings, galvanized fastener, stainless steel fas...

Do you provide customized product services?

Of course, our professional R&D team can design and produce the products you need according to your specifications and drawings. For example: special size, special control, OEM, etc.

How long will it take for me to get the price?

Please provide product specifications such as material, size, quantity and other requirements. We usually quote within 6 hours, and steel prices fluctuate with the market every day. Our prices are ver...

Can we visit your factory?

Of course, we welcome you to visit our factory on site or visit our production line through online video to understand our strength and quality. We will arrange a professional team to serve you.You ju...

How do you ensure the quality of your products?

All products must be inspected three times during the entire manufacturing process, including production, cutting and packaging. Factory inspection report is provided with the goods. If necessary, thi...

How can I trust you?

We believe honesty is the life of our company. We welcome you to visit our factory in Shandong, China, and inspect our company, factory and products through video, live broadcast and other methods.

How can I get samples? What's the fare?

Depending on the specifications of the product, we are sure to provide free samples or paid samples. You just need to provide us with your needs.

What is your delivery time?

Different products and purchase quantities have different delivery times. Products will be delivered as soon as possible on the basis of quality assurance. Usually, it takes 7-14 days if the goods are...

What is the transaction process for your inventory products?

We have various types and sizes of products for you to choose from. After communication and product selection: 1. We will recommend the most suitable transportation method and cost for you. 2. Check t...